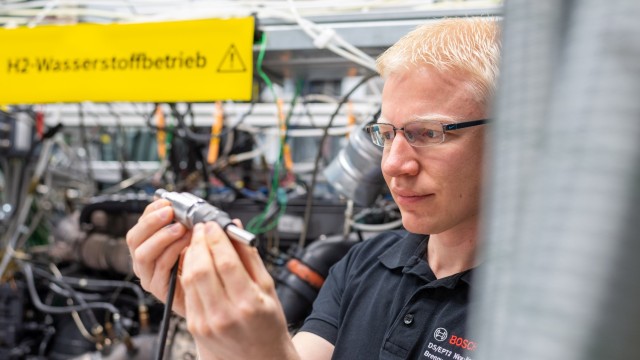

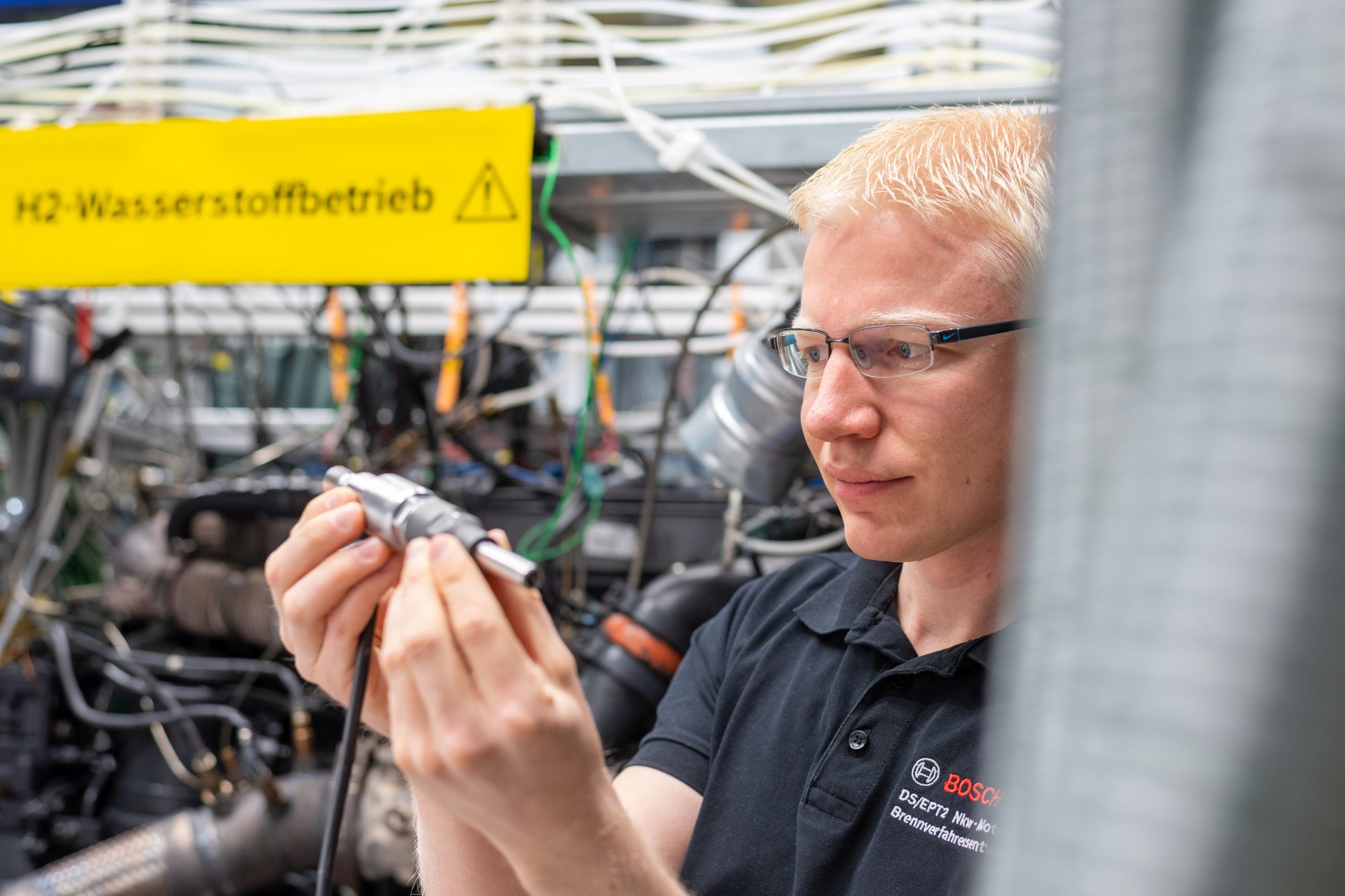

As different as the tasks of agricultural machinery are, all these vehicles have one thing in common: a diesel engine. Yet its use in the agricultural sector alone accounts for some 5 percent of Germany’s diesel consumption. Clearly, agricultural machinery needs to become more climate friendly. Bosch sees hydrogen, which can also be used to power heavy vehicles, as essential for achieving climate neutrality. With its solutions for the hydrogen engine, which can also serve as a suitable drive for specific applications in agriculture, the company wants to move further toward the establishment of a hydrogen economy. At Agritechnica 2023, it will be premiering a technical innovation: an injector for direct hydrogen injection that requires no additional lubrication. “Technologically, the new hydrogen injector for direct injection is a great leap forward,” says Jan-Oliver Röhrl, the executive vice president responsible for commercial vehicle powertrains in the Bosch Powertrain Solutions division.

About Bosch

Bosch has been present in the Netherlands since 1903. The Bosch Group employs approximately 3,000 associates in the Netherlands. Major manufacturing facilities are located in Tilburg, Boxtel & Deventer.

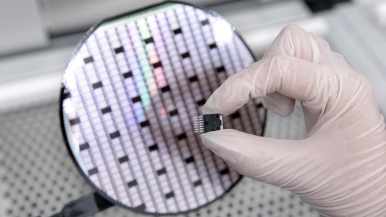

The Bosch Group is a leading global supplier of technology and services. It employs roughly 429,000 associates worldwide (as of December 31, 2023). The company generated sales of 91.6 billion euros in 2023. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 90,000 associates in research and development, of which roughly 48,000 are software engineers.

The company was set up in Stuttgart in 1886 by Robert Bosch (1861–1942) as “Workshop for Precision Mechanics and Electrical Engineering.” The special ownership structure of Robert Bosch GmbH guarantees the entrepreneurial freedom of the Bosch Group, making it possible for the company to plan over the long term and to undertake significant upfront investments in the safeguarding of its future. Ninety-four percent of the share capital of Robert Bosch GmbH is held by Robert Bosch Stiftung GmbH, a charitable foundation. The remaining shares are held by Robert Bosch GmbH and by a corporation owned by the Bosch family. The majority of voting rights are held by Robert Bosch Industrietreuhand KG, an industrial trust. It is entrusted with the task of safeguarding the company’s long-term existence and in particular its financial independence – in line with the mission handed down in the will of the company’s founder, Robert Bosch.

Additional information is available online at www.bosch-press.nl, www.bosch.nl, www.bosch.com, www.iot.bosch.com, Twitter, LinkedIn and YouTube: Bosch the Netherlands.