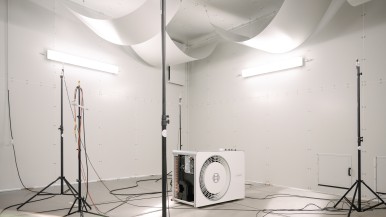

It is a real headache, as well as a potential cause of delay, when vehicles such as excavators or dump trucks cannot be located on huge construction sites. Where exactly are my vehicles? And how many hours have they been in operation? It is questions like these that fleet operators in the construction industry and agricultural sector have to be able to answer if they want to deploy their vehicles as efficiently as possible. This is where the Bosch asset tracing solution – or Bosch TRACI for short – comes into its own. The robust, IoT-based connectivity solution can be easily retrofitted to existing vehicles. “Bosch TRACI provides all the relevant data needed to enhance the efficiency and utilization rate of any vehicle fleet,” says Jan Philipp Büchner, the product manager responsible for Bosch TRACI. “It helps keep wait, search, and transportation times to a minimum.” The Bosch solution comprises a sensor box, cloud-based evaluation software, and a wide array of digital services.

About Bosch

Bosch has been present in the Netherlands since 1903. The Bosch Group employs approximately 3,050 associates in the Netherlands. Major manufacturing facilities are located in Tilburg, Boxtel & Deventer.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 428,000 associates worldwide (as of December 31, 2023). According to preliminary figures, the company generated sales of 91.6 billion euros in 2023. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 136 locations across the globe, Bosch employs some 90,000 associates in research and development, of which roughly 48,000 are software engineers.

The company was set up in Stuttgart in 1886 by Robert Bosch (1861–1942) as “Workshop for Precision Mechanics and Electrical Engineering.” The special ownership structure of Robert Bosch GmbH guarantees the entrepreneurial freedom of the Bosch Group, making it possible for the company to plan over the long term and to undertake significant upfront investments in the safeguarding of its future. Ninety-four percent of the share capital of Robert Bosch GmbH is held by Robert Bosch Stiftung GmbH, a charitable foundation. The remaining shares are held by Robert Bosch GmbH and by a corporation owned by the Bosch family. The majority of voting rights are held by Robert Bosch Industrietreuhand KG, an industrial trust. The entrepreneurial ownership functions are carried out by the trust.

Additional information is available online at op www.bosch-press.nl, www.bosch.nl, www.bosch.com, www.iot.bosch.com, Twitter, LinkedIn and YouTube: Bosch the Netherlands.